| 产品分类 |

|

|

嘉善双禾无油轴承厂

地址:中国浙江嘉善县干窑工业区

电话:0573-84517192

传真:0573-84516677

手机:13857306970

联系人:顾先生

网址:www.jsshwyzc.com |

|

|

|

无油复合轴承

|

| SF-1B 铜基无给油轴承 |

|

|

| 产品描述 |

|

nter">30 -0.020

-0.041

|

34 +0.025

|

34 +0.085

+0.045

|

29.990

30.285

|

|

|

|

3012

|

3015

|

3020

|

3025

|

3030

|

3040

|

|

|

|

32 -0.025

-0.050

|

36 +0.025

|

36 +0.085

+0.045

|

31.990

32.085

|

|

|

|

|

|

3220

|

|

3230

|

3240

|

|

|

|

35 -0.025

-0.050

|

39 +0.025

|

39 +0.085

+0.045

|

34.990

35.085

|

|

|

|

3512

|

3515

|

3520

|

3525

|

3530

|

3540

|

3550

|

|

|

38 -0.025

-0.050

|

42 +0.025

|

42 +0.085

+0.045

|

37.990

38.085

|

|

|

|

|

3815

|

|

|

3830

|

3840

|

|

|

|

40 -0.025

-0.050

|

44 +0.025

|

44 +0.085

+0.045

|

39.990

40.085

|

|

|

|

4012

|

|

4020

|

4025

|

4030

|

4040

|

4050

|

|

|

相配轴径公差

|

相配座孔公差

(H7 )

|

轴承外径公差

|

压入座孔后轴承内径公差

|

壁厚

|

f1

|

f2

|

L0-0.40

|

|

20

|

25

|

30

|

40

|

50

|

60

|

70

|

80

|

100

|

115

|

|

45 -0.025

-0.050

|

50 +0.025

|

50 +0.085

+0.045

|

44.990

45.105

|

2.460

2.505

|

1.8

|

0.6

|

4520

|

4525

|

4530

|

4540

|

4550

|

|

|

|

|

|

|

50 -0.025

-0.050

|

55 +0.030

|

55 +0.100

+0.055

|

49.990

50.110

|

5020

|

|

5030

|

5040

|

5050

|

5060

|

|

|

|

|

|

55 -0.030

-0.060

|

60 +0.030

|

60 +0.100

+0.055

|

54.990

55.110

|

|

|

5530

|

5540

|

5550

|

5560

|

|

|

|

|

|

60 -0.030

-0.060

|

65 +0.030

|

65 +0.100

+0.055

|

59.990

60.110

|

|

|

6030

|

6040

|

6050

|

6060

|

6070

|

|

|

|

|

65 -0.030

-0.060

|

70 +0.030

|

70 +0.100

+0.055

|

64.990

65.110

|

|

|

6530

|

6540

|

6550

|

6560

|

6570

|

|

|

|

|

70 -0.030

-0.060

|

75 +0.030

|

75 +0.100

+0.055

|

69.990

70.110

|

|

|

|

7040

|

7050

|

7060

|

7070

|

7080

|

|

|

|

75 -0.030

-0.060

|

80 +0.030

|

80 +0.100

+0.055

|

74.990

75.110

|

|

|

7530

|

7540

|

7550

|

7560

|

7570

|

7580

|

|

|

|

80 -0.030

|

85 +0.035

|

85 +0.120

+0.070

|

80.020

80.155

|

2.440

2.490

|

1.8

|

0.6

|

|

|

|

8040

|

8050

|

8060

|

8070

|

8080

|

80100

|

|

|

85 -0.035

|

90 +0.035

|

90 +0.120

+0.070

|

85.020

85.155

|

|

|

|

8540

|

|

8560

|

|

8580

|

85100

|

|

|

90 -0.035

|

95 +0.035

|

95 +0.120

+0.070

|

90.020

90.155

|

|

|

|

9040

|

9050

|

9060

|

|

9080

|

90100

|

|

|

95 -0.035

|

100 +0.035

|

100 +0.120

+0.070

|

95.020

95.155

|

|

|

|

|

9550

|

9560

|

|

9580

|

95100

|

|

|

100 -0.035

|

105 +0.035

|

105 +0.120

+0.070

|

100.020

100.155

|

|

|

|

|

10050

|

10060

|

|

10080

|

|

100115

|

|

105 -0.035

|

110 +0.035

|

110 +0.120

+0.070

|

105.020

105.155

|

|

|

|

|

|

10560

|

|

10580

|

|

105115

|

|

110 -0.035

|

115 +0.035

|

115 +0.120

+0.070

|

110.020

110.155

|

|

|

|

|

|

11060

|

|

11080

|

|

110115

|

|

120 -0.035

|

125 +0.040

|

125 +0.170

+0.100

|

120.070

120.210

|

2.415

2.465

|

1.8

|

0.6

|

|

|

|

|

|

12060

|

|

12080

|

112100

|

|

|

125 -0.040

|

130 +0.040

|

130 +0.170

+0.100

|

125.070

125.210

|

|

|

|

|

|

12560

|

|

|

125100

|

125115

|

|

130 -0.040

|

135 +0.040

|

135 +0.170

+0.100

|

130.070

130.210

|

|

|

|

|

|

13060

|

|

13080

|

130100

|

|

|

140 -0.040

|

145 +0.040

|

145 +0.170

+0.100

|

140.070

140.210

|

|

|

|

|

|

14060

|

|

14080

|

140100

|

|

|

150 -0.040

|

155 +0.040

|

155 +0.170

+0.100

|

150.070

150.210

|

|

|

|

|

|

15060

|

|

15080

|

150100

|

|

|

160 -0.040

|

165 +0.040

|

165 +0.170

+0.100

|

160.070

160.210

|

|

|

|

|

|

16060

|

|

16080

|

160100

|

160115

|

|

180 -0.040

|

185 +0.046

|

185 +0.210

+0.130

|

180.070

180.216

|

|

|

|

|

|

|

|

|

|

|

18080

|

180100

|

|

|

190 -0.046

|

195 +0.046

|

195 +0.210

+0.130

|

190.070

190.216

|

|

|

|

|

|

|

|

19080

|

190100

|

|

|

200 -0.046

|

205 +0.046

|

205 +0.210

+0.130

|

200.070

200.216

|

|

|

|

|

|

20060

|

|

20080

|

200100

|

|

|

220 -0.046

|

225 +0.046

|

225 +0.210

+0.130

|

220.070

220.216

|

|

|

|

|

|

|

|

22080

|

220100

|

|

|

250 -0.046

|

255 +0.052

|

255 +0.260

+0.170

|

250.070

250.222

|

|

|

|

|

|

|

|

25080

|

250100

|

|

|

260 -0.052

|

265 +0.052

|

265 +0.260

+0.170

|

260.070

260.222

|

|

|

|

|

|

|

|

26080

|

260100

|

|

|

280 -0.052

|

285 +0.052

|

285 +0.260

+0.170

|

280.070

280.222

|

|

|

|

|

|

|

|

28080

|

280100

|

|

|

300 -0.052

|

305 +0.052

|

305 +0.260

+0.170

|

300.070

300.222

|

|

|

|

|

|

|

|

30080

|

300100

|

|

|

|

|

,  1. 改性聚四氟乙烯(PTFE)以及铅(Pb)的混合物 0.01-0.03mm,一种耐磨材料,运作过程中可形成转移膜,以保护对磨轴。 1. 改性聚四氟乙烯(PTFE)以及铅(Pb)的混合物 0.01-0.03mm,一种耐磨材料,运作过程中可形成转移膜,以保护对磨轴。

2. 铜粉层,0.20-0.3mm,提高PTFE/Pb与铜板层的结合强度,具有很好的承载能力和耐磨性。较高的导热系数可迅速转移运作过程产生的热量。

3. 铜基板0.7~2.3,提高轴承的承载能力和热传递,且有更好的耐腐蚀能力。

主要参数 TECHNICAL DATE

|

|

静承载

|

250N/mm2

|

摩擦系数

|

0.03~0.20

|

|

最大承载

|

低速运转

|

140N/mm2

|

最大线速度

|

干摩擦

|

2m/s

|

| |

旋转、摇摆运动

|

60N/mm2

|

|

流体润滑

|

5m/s

|

|

最大PV值

(干摩擦)

|

间断性运作

|

3.6N/mm2.m/s

|

导热系数 |

42W(m.K)-1

|

| |

长期运作

|

1.8N/mm2.m/s

|

线膨胀系数

|

11x11-6K

|

|

使用温度

|

-195℃~+280℃

|

|

| 应用特点 APPLICATION CHARACTER |

|

除了与SF-1相同的优点外,还具有以下特性:

由于铜本身具有其自润性能,所以可用于需长时间工作而无法停机维修的部位,具有比SF-1更好的抗腐蚀性能。广泛运用于弱酸强碱场合、港口机械、船舶机械、冶金钢铁工业,连铸机方坯滚道、高温炉钢环部位、水泥灌浆泵和螺旋式输送机上。它可以在外部组合钢套,或制成翻边,端面、内孔同时摩擦使用。

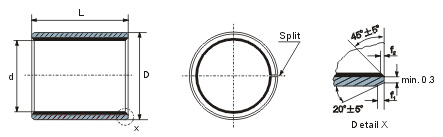

SF-1B标准公差尺寸表

|

相配轴径公差

|

相配座孔公差

(H7 )

|

轴承外径公差

tolerance

|

压入座孔后轴承内径公差

|

Wall

thick-

ness

壁厚

|

f1

|

f2

|

| L0-0.40 |

(d≤φ30 L -0.3

d>φ30 L -0.4) |

|

|

6

|

8

|

10

|

12

|

15

|

20

|

25

|

30

|

40

|

50

|

60

|

|

6 -0.013

-0.028

|

8 +0.015

|

8 +0.055

+0.025

|

5.990

6.055

|

0.980

1.005

|

0.6

|

0.3

|

0606

|

0608

|

0610

|

|

|

|

|

|

|

|

|

|

8 -0.013

-0.028

|

10 +0.015

|

10 +0.055

+0.025

|

7.990

8.055

|

0806

|

0808

|

0810

|

08012

|

08015

|

|

|

|

|

|

|

|

10 -0.016

-0.034

|

12 +0.018

|

12 +0.065

+0.030

|

9.990

10.058

|

1006

|

1008

|

1010

|

1012

|

1015

|

1020

|

|

|

|

|

|

|

12 -0.016

-0.034

|

14 +0.018

|

14 +0.065

+0.030

|

11.990

12.058

|

1206

|

1208

|

1210

|

1212

|

1215

|

1220

|

1225

|

|

|

|

|

|

13 -0.016

-0.034

|

15 +0.018

|

15 +0.065

+0.030

|

12.990

13.058

|

|

|

1310

|

|

|

1320

|

|

|

|

|

|

|

14 -0.016

-0.034

|

16 +0.018

|

16+0.065

+0.030

|

13.990

14.058

|

|

|

1410

|

1412

|

1415

|

1420

|

1425

|

|

|

|

|

|

15 -0.016

-0.034

|

17 +0.018

|

17+0.065

+0.030

|

14.990

15.058

|

|

|

1510

|

1512

|

1515

|

1520

|

1525

|

|

|

|

|

|

16 -0.016

-0.034

|

18 +0.018

|

18 +0.065

+0.030

|

15.990

16.058

|

|

|

1610

|

1612

|

1615

|

1620

|

1625

|

|

|

|

|

|

17 -0.016

-0.034

|

19 +0.021

|

19 +0.075

+0.035

|

16.990

17.061

|

|

|

1710

|

1712

|

|

1720

|

|

|

|

|

|

|

18 -0.016

-0.034

|

20 +0.021

|

20 +0.075

+0.035

|

17.990

18.061

|

|

|

1810

|

1812

|

1815

|

1820

|

1825

|

|

|

|

|

|

20 -0.020

-0.041

|

23 +0.021

|

23 +0.075

+0.035

|

19.990

20.071

|

1.475

1.505

|

0.6

|

0.4

|

|

|

2010

|

2012

|

2015

|

2020

|

2025

|

2030

|

|

|

|

|

22 -0.020

-0.041

|

25 +0.021

|

25 +0.075

+0.035

|

21.990

22.071

|

|

|

2210

|

2212

|

2215

|

2220

|

2225

|

2230

|

|

|

|

|

24 -0.020

-0.041

|

27 +0.021

|

27 +0.075

+0.035

|

23.990

24.071

|

|

|

|

|

2415

|

2420

|

2425

|

2430

|

|

|

|

|

25 -0.020

-0.041

|

28 +0.021

|

28 +0.075

+0.035

|

24.990

25.071

|

|

|

2510

|

2512

|

2515

|

2520

|

2525

|

2530

|

2540

|

2550

|

|

|

28 -0.020

-0.041

|

32 +0.025

|

32 +0.085

+0.045

|

27.990

28.085

|

1.970

2.005

|

1.2

|

0.4

|

|

|

|

|

2815

|

2820

|

2825

|

2830

|

2840

|

|

|

|

|

| | | |